A dedicated solution to your circular challenges

Track, control, and optimise reusable packaging across complex, multi-party supply chains.

Manufacturing

Packaging Producers

Onboard new partners and locations quickly without breaking visibility or control.

Manufacturing

Packaging Producers

Onboard new partners and locations quickly without breaking visibility or control.

Manufacturing

Packaging Producers

Onboard new partners and locations quickly without breaking visibility or control.

Partners

Pooling & fleet operators

Reduce manual tracking, exception handling, and dispute resolution across the chain.

Partners

Pooling & fleet operators

Reduce manual tracking, exception handling, and dispute resolution across the chain.

Partners

Pooling & fleet operators

Reduce manual tracking, exception handling, and dispute resolution across the chain.

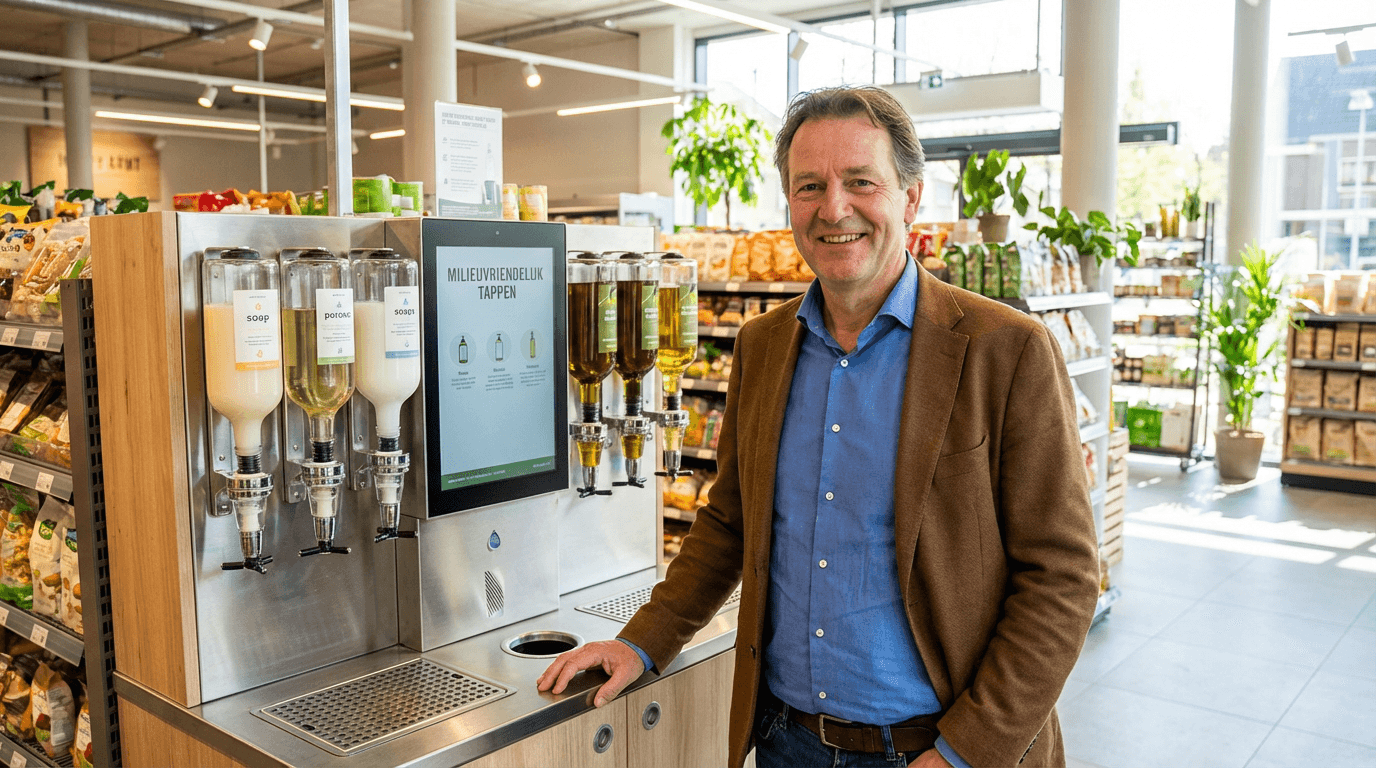

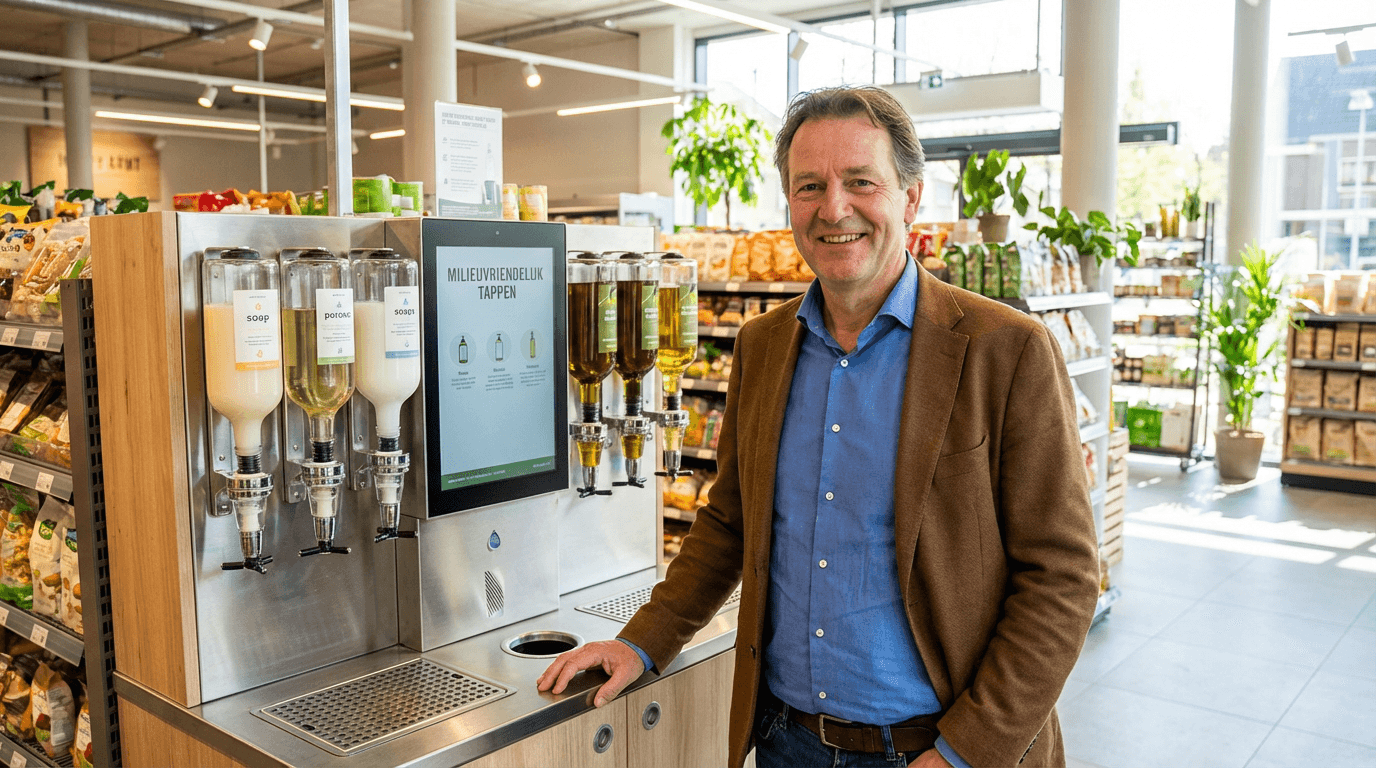

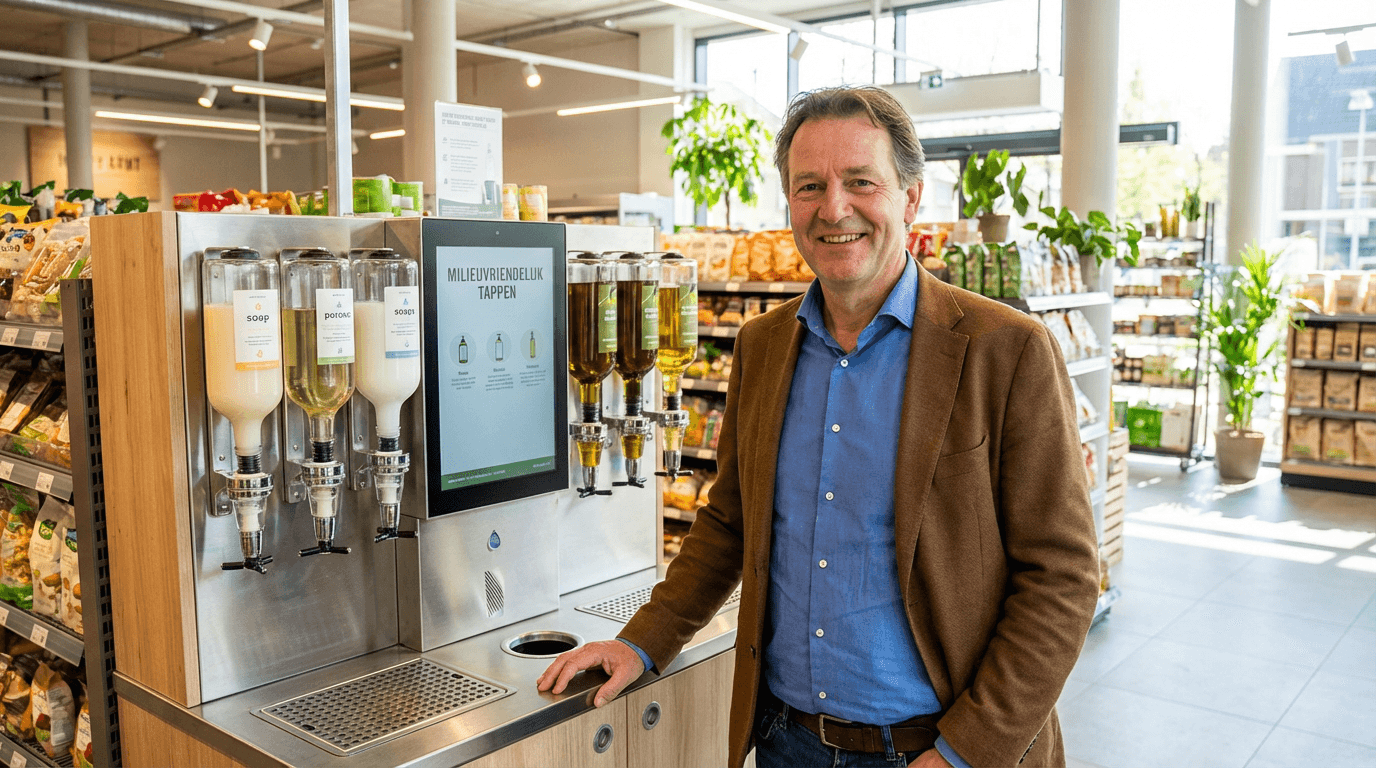

B2B2C packaging

Brands and retailers

Onboard new partners and locations quickly without breaking visibility or control.

B2B2C packaging

Brands and retailers

Onboard new partners and locations quickly without breaking visibility or control.

B2B2C packaging

Brands and retailers

Onboard new partners and locations quickly without breaking visibility or control.

Partners

Logistics service providers

Reduce manual tracking, exception handling, and dispute resolution across the chain.

Partners

Logistics service providers

Reduce manual tracking, exception handling, and dispute resolution across the chain.

Partners

Logistics service providers

Reduce manual tracking, exception handling, and dispute resolution across the chain.

Why companies are rethinking reusable packaging

Reusable carriers are introduced with good intentions, but managed with tools designed for linear flows. Control degrades as complexity increases.

Reusables as a side-effect

Carriers treated as anonymous units, not assets

Visibility limited to handover moments or depots

Loss explained away as “part of the system”

Manual reconciliation across partners & Excels

Scaling the network increases friction and cost

Circularity depends on discipline instead of design

Built specifically for modern finance operations.

Clean, intuitive interface designed for speed.

One platform — expenses, budgets, vendors.

Smart approval flows with built-in controls.

Real-time insights with budget health indicators.

Up and running in days with guided implementation.

Transparent pricing with everything included.

Dynamic, customizable reports you can actually use.

Reusables as a side-effect

Carriers treated as anonymous units, not assets

Visibility limited to handover moments or depots

Loss explained away as “part of the system”

Manual reconciliation across partners & Excels

Scaling the network increases friction and cost

Circularity depends on discipline instead of design

Built specifically for modern finance operations.

Clean, intuitive interface designed for speed.

One platform — expenses, budgets, vendors.

Smart approval flows with built-in controls.

Real-time insights with budget health indicators.

Up and running in days with guided implementation.

Transparent pricing with everything included.

Dynamic, customizable reports you can actually use.

Reusables as a side-effect

Carriers treated as anonymous units, not assets

Visibility limited to handover moments or depots

Loss explained away as “part of the system”

Manual reconciliation across partners & Excels

Scaling the network increases friction and cost

Circularity depends on discipline instead of design

Built specifically for modern finance operations.

Clean, intuitive interface designed for speed.

One platform — expenses, budgets, vendors.

Smart approval flows with built-in controls.

Real-time insights with budget health indicators.

Up and running in days with guided implementation.

Transparent pricing with everything included.

Dynamic, customizable reports you can actually use.

Integrate once. Sync everywhere. Rotion plays well with the tools you already use.

From ERPs to HR and accounting tools, Rotion plugs into your finance stack to keep data consistent, workflows tight, and teams aligned.

Frequently asked questions

Answers to common questions about getting started and using Rotion day to day.

Book a demo call

Let’s talk about your current setup or ambitions and see how Rotion can simplify your circular logistics.

Do you prefer email? We're available at:

Book a demo call

Let’s talk about your current setup or ambitions and see how Rotion can simplify your circular logistics.

Do you prefer email? We're available at:

Book a demo call

Let’s talk about your current setup or ambitions and see how Rotion can simplify your circular logistics.

Do you prefer email? We're available at:

Rotion is not just about knowing where assets were last scanned. It creates a digital twin for every asset, logs its full lifecycle across partners, and uses that data to surface inefficiencies, loss, and bottlenecks. It is built to manage reusable packaging as a system, not as a series of handovers.

No. Rotion is designed for multi-party environments where not every partner has the same level of integration or maturity. Partners can interact via web apps, mobile apps, or integrations, with role-based access that limits what they see and do.h step — from connecting your systems to configuring your reports and permissions. We also provide live chat support and optional training sessions if you need more hands-on help.

Yes. Rotion supports QR codes, barcodes, RFID, or combinations of these. Existing codes can be reused where possible, so relabeling or new hardware is not mandatory.

Yes. Vectura includes fine-grained permission controls out of the box. You can assign roles baseRotion supports temporary batching using SSCCs, allowing multiple assets to be scanned as one group through several process steps. This significantly reduces scan volume while maintaining asset-level traceability.d on department, job function, or access level — whether someone needs full visibility, approval rights, or just access to their team's budgets.

Rotion provides real-time operational KPIs such as availability, utilization, cycle time, dwell time, loss rates, and damage patterns. AI-based anomaly detection highlights unusual behavior so teams can focus on the issues that have the highest cost impact.

Yes. The platform is built to handle millions of assets, high scan volumes, and complex, multi-location supply chains. Deployment options include cloud, private instances, and on-premise environments to meet enterprise requirements.

Rotion is not just about knowing where assets were last scanned. It creates a digital twin for every asset, logs its full lifecycle across partners, and uses that data to surface inefficiencies, loss, and bottlenecks. It is built to manage reusable packaging as a system, not as a series of handovers.

No. Rotion is designed for multi-party environments where not every partner has the same level of integration or maturity. Partners can interact via web apps, mobile apps, or integrations, with role-based access that limits what they see and do.h step — from connecting your systems to configuring your reports and permissions. We also provide live chat support and optional training sessions if you need more hands-on help.

Yes. Rotion supports QR codes, barcodes, RFID, or combinations of these. Existing codes can be reused where possible, so relabeling or new hardware is not mandatory.

Yes. Vectura includes fine-grained permission controls out of the box. You can assign roles baseRotion supports temporary batching using SSCCs, allowing multiple assets to be scanned as one group through several process steps. This significantly reduces scan volume while maintaining asset-level traceability.d on department, job function, or access level — whether someone needs full visibility, approval rights, or just access to their team's budgets.

Rotion provides real-time operational KPIs such as availability, utilization, cycle time, dwell time, loss rates, and damage patterns. AI-based anomaly detection highlights unusual behavior so teams can focus on the issues that have the highest cost impact.

Yes. The platform is built to handle millions of assets, high scan volumes, and complex, multi-location supply chains. Deployment options include cloud, private instances, and on-premise environments to meet enterprise requirements.

Rotion is not just about knowing where assets were last scanned. It creates a digital twin for every asset, logs its full lifecycle across partners, and uses that data to surface inefficiencies, loss, and bottlenecks. It is built to manage reusable packaging as a system, not as a series of handovers.

No. Rotion is designed for multi-party environments where not every partner has the same level of integration or maturity. Partners can interact via web apps, mobile apps, or integrations, with role-based access that limits what they see and do.h step — from connecting your systems to configuring your reports and permissions. We also provide live chat support and optional training sessions if you need more hands-on help.

Yes. Rotion supports QR codes, barcodes, RFID, or combinations of these. Existing codes can be reused where possible, so relabeling or new hardware is not mandatory.

Yes. Vectura includes fine-grained permission controls out of the box. You can assign roles baseRotion supports temporary batching using SSCCs, allowing multiple assets to be scanned as one group through several process steps. This significantly reduces scan volume while maintaining asset-level traceability.d on department, job function, or access level — whether someone needs full visibility, approval rights, or just access to their team's budgets.

Rotion provides real-time operational KPIs such as availability, utilization, cycle time, dwell time, loss rates, and damage patterns. AI-based anomaly detection highlights unusual behavior so teams can focus on the issues that have the highest cost impact.

Yes. The platform is built to handle millions of assets, high scan volumes, and complex, multi-location supply chains. Deployment options include cloud, private instances, and on-premise environments to meet enterprise requirements.