The Scale Gap: Why Reusable Packaging Systems Fail to Scale

Why reusable packaging systems break at volume and how to build for industrial scale, with a hollistic software solution like Rotion.

Maarten Tak

CEO

Table of contents

Share

Across the global supply chain, thousands of "Circular Packaging" pilots are currently underway. Most are technically successful—the materials hold up, the consumers participate, and the assets return. Yet, less than 5% of these pilots transition to full-scale industrial operations.

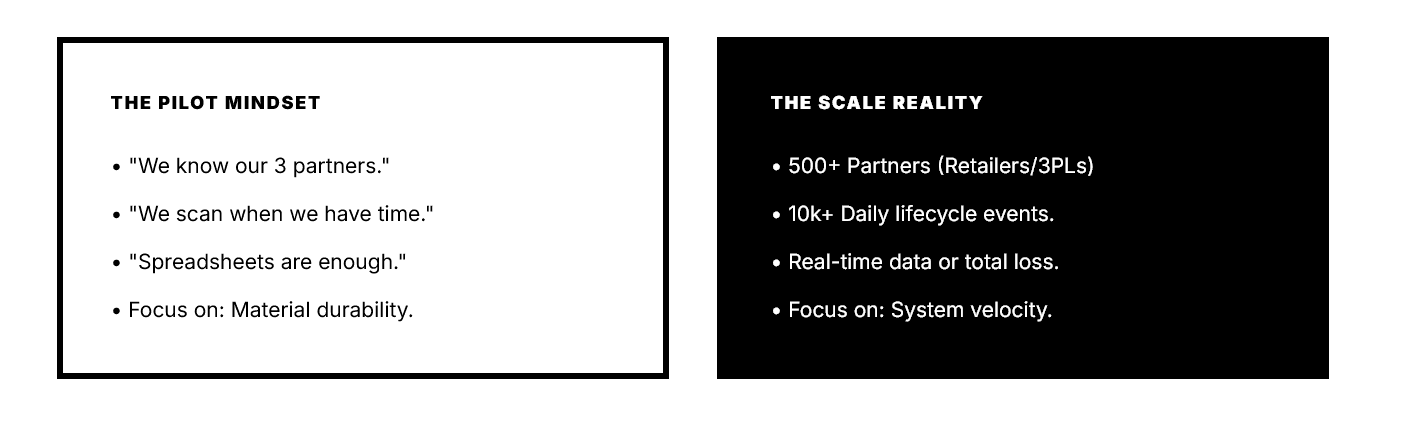

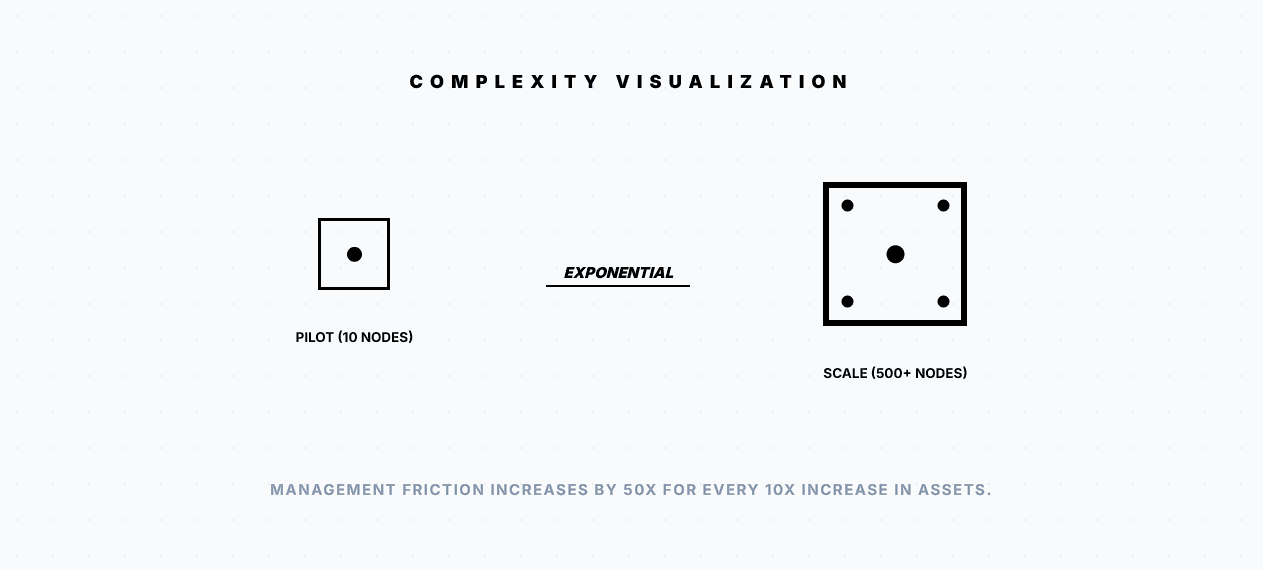

This is what we call Pilot Purgatory. It is the result of a fundamental misunderstanding: the belief that a system that manages 1,000 crates can be linearly expanded to manage 1,000,000. In reality, the complexity of a reusable system does not grow linearly—it grows exponentially.

01. The Illusion of Manual Control

At the pilot stage (typically 500 to 5,000 assets), control is an illusion. You can track assets using a shared spreadsheet, manual emails, and a few dedicated staff members who "manually reconcile" missing inventory at the end of each month.

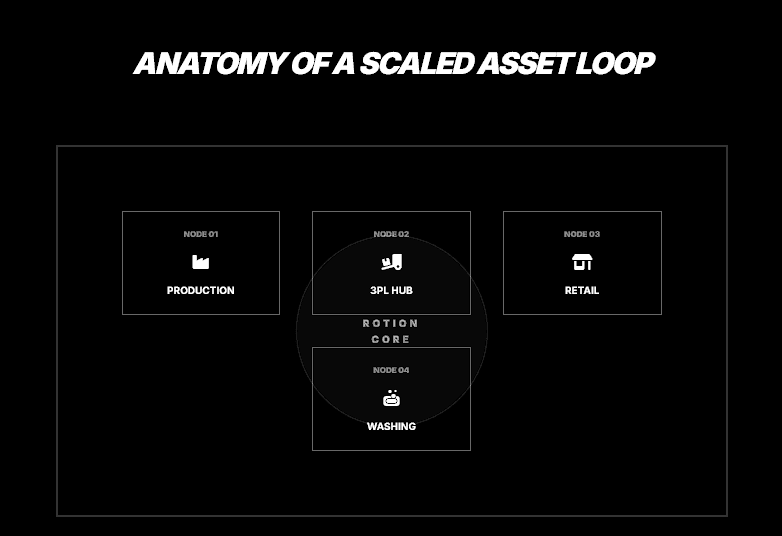

When you move to 1,000,000 assets, you aren't just managing more crates; you are managing a multi-party data ecosystem. Every handover between a brand, a logistics provider, a retailer, and a washing facility is a potential point of data failure. Without a digital system of record, the "manual reconciliation" that worked for 1,000 units becomes a full-time nightmare for 100 people.

02. The Complexity Explosion

Why does the system break? Because of the Interconnectivity Gap. In a linear model, a box moves from A to B and disappears. In a circular model, an asset moves from A to B to C to D and back to A.

As you scale, the number of possible paths an asset can take increases. If you have 10 retail locations and 1 washing partner, you have 10 loops. If you have 500 retail locations and 5 washing partners, you have thousands of potential loops. If the status of an asset is not updated in real-time at every node, you lose the ability to predict availability.=

03. The Three Scale-Killers

Through our work at Rotion, we have identified three specific bottlenecks that kill large-scale reuse projects:

The "Scanning Tax"

In high-volume warehouses, every second counts. If a reusable system requires an operator to stop their workflow and scan 50 individual crates on a pallet, that system will be ignored. Workers will skip the scan to hit their throughput targets, leading to a "Data Black Hole" where you know how many crates you bought, but not where they are.

The Trust Deficit

Multi-party systems require shared accountability. If a Brand claims they shipped 100 crates to a Retailer, but the Retailer claims they only received 80, who is responsible for the loss? Without a neutral, digital system of record, these disputes lead to legal friction and project abandonment.

Static Decision Making

At scale, you cannot make decisions based on last month's inventory report. You need to know today's dwell times. If assets are sitting at a washing facility for 5 days instead of 1, you are losing money every hour. Scaled systems require real-time exception management, not retrospective reporting.

04. How Rotion Bridges the Gap

Rotion was built specifically to solve the Scale Gap. We move beyond "blind shipping" by providing a digital infrastructure that treats every crate as a high-performance data node. We bridge the gap through four foundational technologies designed for the billion-unit future:

I. SSCC Batching (The Throughput Engine)

The "Scanning Tax" is the #1 reason data fails at scale. Rotion’s primary solution is SSCC (Serial Shipping Container Code) Batching. We utilize a parent-child logic: an operator creates a temporary digital batch (a pallet) containing hundreds of unique children (crates).

A single scan of the pallet label moves the entire inventory through the supply chain. This maintains the high-speed throughput required by 3PLs while preserving the individual lifecycle integrity of every single crate in the Rotion cloud.

II. Interoperable Digital Passports

Circular systems are multi-party by nature. Rotion ensures that an asset's digital identity follows it across different ERP and WMS environments (from Odoo to SAP and beyond).

By utilizing GS1-compliant identifiers, we create a "Digital Packaging Passport." This persistent record logs every lifecycle event—shipment, receipt, wash, and repair—ensuring a "Single Operational Truth" that prevents the "Trust Deficit" and eliminates disputes over missing inventory.

III. AI Anomaly Detection (Proactive Governance)

Management at scale must be automated. Rotion doesn't just show you where things are; it tells you when things are wrong. Our AI constantly monitors the fleet for:

• Abnormal Dwell Times (Assets sitting idle too long)

• Missing Returns (Detecting leakage before it becomes a write-off)

• Route Deviations (Unauthorized movement outside the loop)

This "Management by Exception" approach allows a small team to manage a fleet of millions, focusing only on the high-impact bottlenecks that actually cost money.

IV. Inclusive QC & Washing Workflows

Circular scale depends on high-quality assets. Rotion integrates washing partners directly into the loop with a Fast Inclusive QC workflow. Designed for diverse work environments—including social economy partners—operators use simple QR codes for rejected states.

A two-scan process (Asset + Reason) ensures that quality control is captured without slowing down the line. This data flows back to the brand, providing deep insights into asset health and partner performance.

Scale is a test of infrastructure, not material.

If your reuse pilot is succeeding, congratulations—you have proven the container. Now, you must prove the system. Don't let your circular ambitions die in Pilot Purgatory. Build the digital foundation before you ship the millionth crate.