Why Linear Packaging Systems NEED to Go Circular

See why Circular Packaging systems are simply a sunk-cost liability, and businesses should opt for Circular Assets instead.

Jonas Janssen

COO

Table of contents

Share

"For fifty years, success in packaging was measured by volume of disposal. Tomorrow, success will be measured by the velocity of reuse. Linear manufacturers who fail to own the data will eventually have nothing to sell."

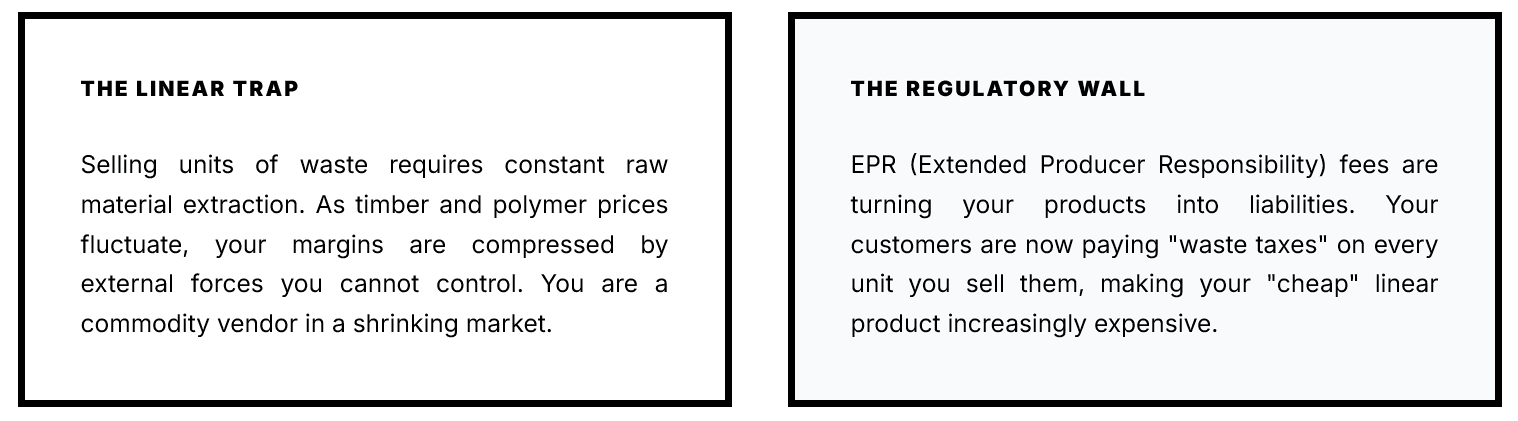

If you are a manufacturer of single-use cardboard or plastic packaging, your business model is currently under a coordinated assault. The traditional "Linear Model"—produce, sell once, and externalize the waste—is hitting a wall of regulatory, financial, and material constraints.

The core logic of your business has always been volume. To grow, you must sell more units. To sell more units, more waste must be generated. This structural link between growth and environmental degradation is no longer just a reputation risk; it is a financial one. From the PPWR in Europe to rising carbon taxes and material scarcity, the "Linear Mirage" is dissipating.

01. The Death of the "Unit" Sale

In the linear model, every unit sold is a sunk cost for your customer. They pay you $0.60 for a box that will be destroyed within 72 hours. This creates a transactional relationship where your only competitive levers are price and proximity.

02. The Circular Pivot: From Sunk Cost to Dividend

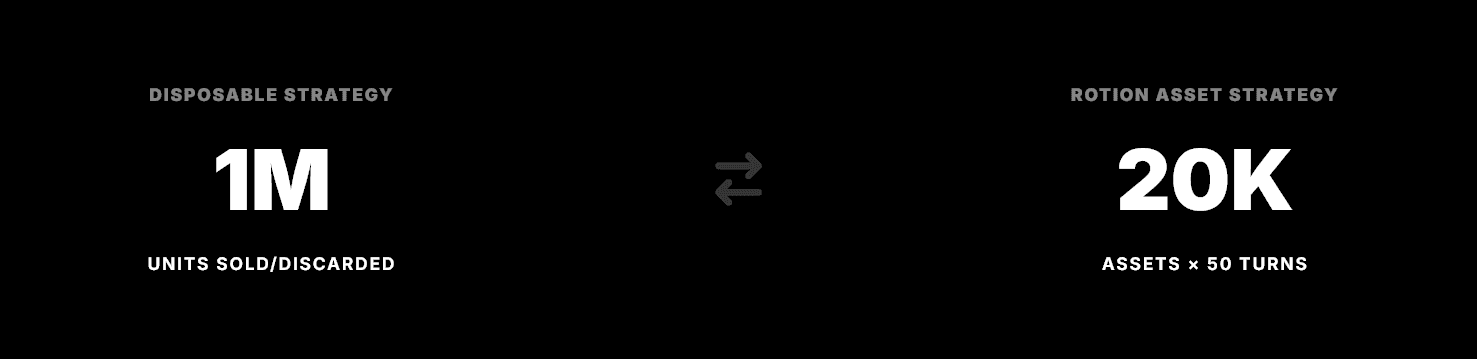

When a linear manufacturer goes circular, they stop selling boxes and start selling trips. Imagine providing your customer with a high-performance, reusable crate. You don't sell it once for $0.60; you lease its performance for 50 cycles.

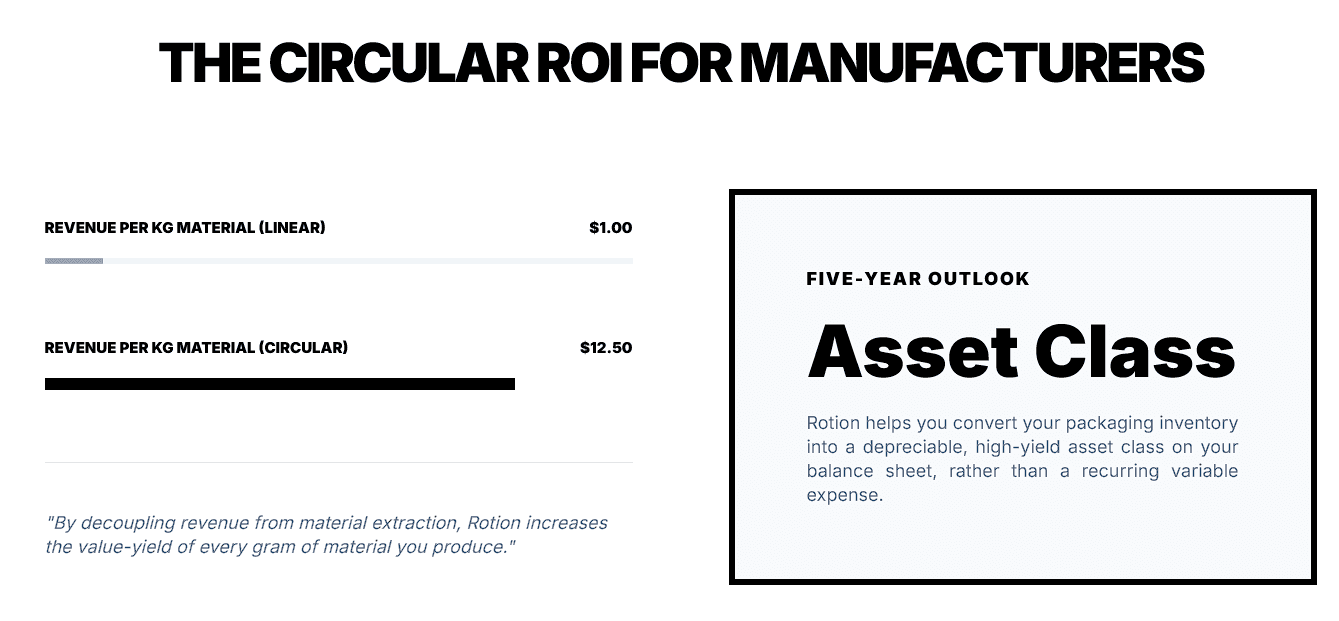

In the circular model, your revenue is decoupled from material consumption. You produce 20,000 durable assets instead of 1,000,000 disposable ones. Your capital remains within the loop. The $8.00 you spend to manufacture a reusable asset is not "lost" once it ships—it is deployed capital that generates a "Circular Dividend" with every turn.

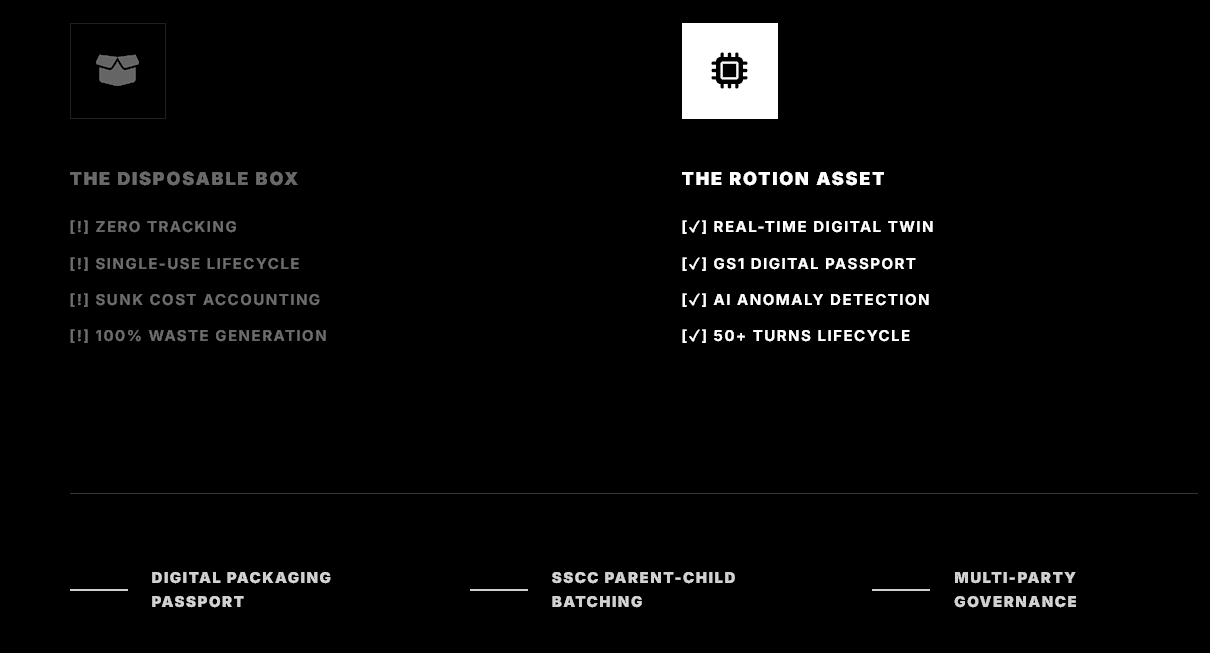

This shift turns your packaging into a high-margin service. You are no longer just selling a container; you are selling the data, the security, and the carbon-reduction that comes with a managed loop. But there is a catch: you cannot manage what you cannot see.

03. Why Linear Manufacturers Fail at Reuse

Most linear manufacturers attempt reuse by simply making their products "thicker" and hoping for the best. This is the Efficiency Trap. Without digitalization, the "Thousand-Dollar Leak" begins:

The Visibility Gap

Once your crate leaves the factory, it enters a "Black Hole." You have no idea if it's at a retailer, a warehouse, or in a landfill. Loss rates in unmanaged systems often exceed 20%, destroying the ROI of the asset.

The Trust Deficit

When an asset disappears, who pays for it? Without a single system of record, your customers and logistics partners will argue over missing inventory. Disputes kill partnerships and scale.

04. Rotion: The System of Record

Rotion provides the digital infrastructure that allows linear manufacturers to transition with certainty. We give your assets the "Digital Brain" they need to survive and thrive in complex supply chains – starting with a Digital Package Passport (DPP).

Transition Pillar 01 // From Volume to Velocity

For a linear manufacturer, Rotion changes the KPI. You no longer worry about how many boxes you sell; you worry about how fast your fleet returns. By using Rotion's AI Anomaly Detection, you can identify bottlenecks at washing facilities or retail back-rooms in real-time. If an asset sits idle for 10 days, the system flags it. Higher velocity equals more revenue from the same pool of assets.

Transition Pillar 02 // Interoperable Governance

Your customers use SAP; your washing partners use Odoo. You need a neutral layer. Rotion uses GS1-compliant identifiers to ensure your "Digital Twin" works in any environment. This prevents vendor lock-in and allows you to offer a "Packaging-as-a-Service" model that fits seamlessly into your customer's existing logistics stack.

Transition Pillar 03 // Removing the Scan Workload

The biggest hurdle to circularity is that it "slows down the line." Rotion's SSCC Batching solves this. You can group individual assets into temporary digital batches. A single scan of a pallet updates 50 assets. This removes the labor penalty of reuse, making your circular offering as fast as your old linear one.

05. The PPWR Clock: Compliance as a Competitive Edge

The window for voluntary circularity is closing. The European Union’s Packaging and Packaging Waste Regulation (PPWR) is transforming the industry from a "best efforts" environment to one of mandatory mandates. For manufacturers of transport packaging, e-commerce shippers, and industrial carriers, the targets are clear: a significant percentage of all packaging must be reusable by 2030, with even steeper requirements by 2040.

Central to this regulation is the concept of the Digital Product Passport (DPP). Compliance will require granular data on material composition, origin, and crucially, the number of successful reuse turns.

Rotion isn't just an operational tool; it is a Compliance Engine. Our Digital Twins automatically generate the audit trails required by PPWR. While your competitors struggle with manual reporting and estimated data, Rotion users will provide verified, real-time proof of system performance. In a PPWR-regulated market, data integrity is no longer optional—it is your license to operate.

By 2030, the ability to track "Turns per Asset" will distinguish market leaders from those facing heavy regulatory penalties.

The Circular ROI for Manufacturers

Own the Loop. Own the Data.

The linear era is ending. Manufacturers who continue to sell "blind units" will be taxed out of existence. Manufacturers who pivot to managed circular loops will own the future of supply chain intelligence.